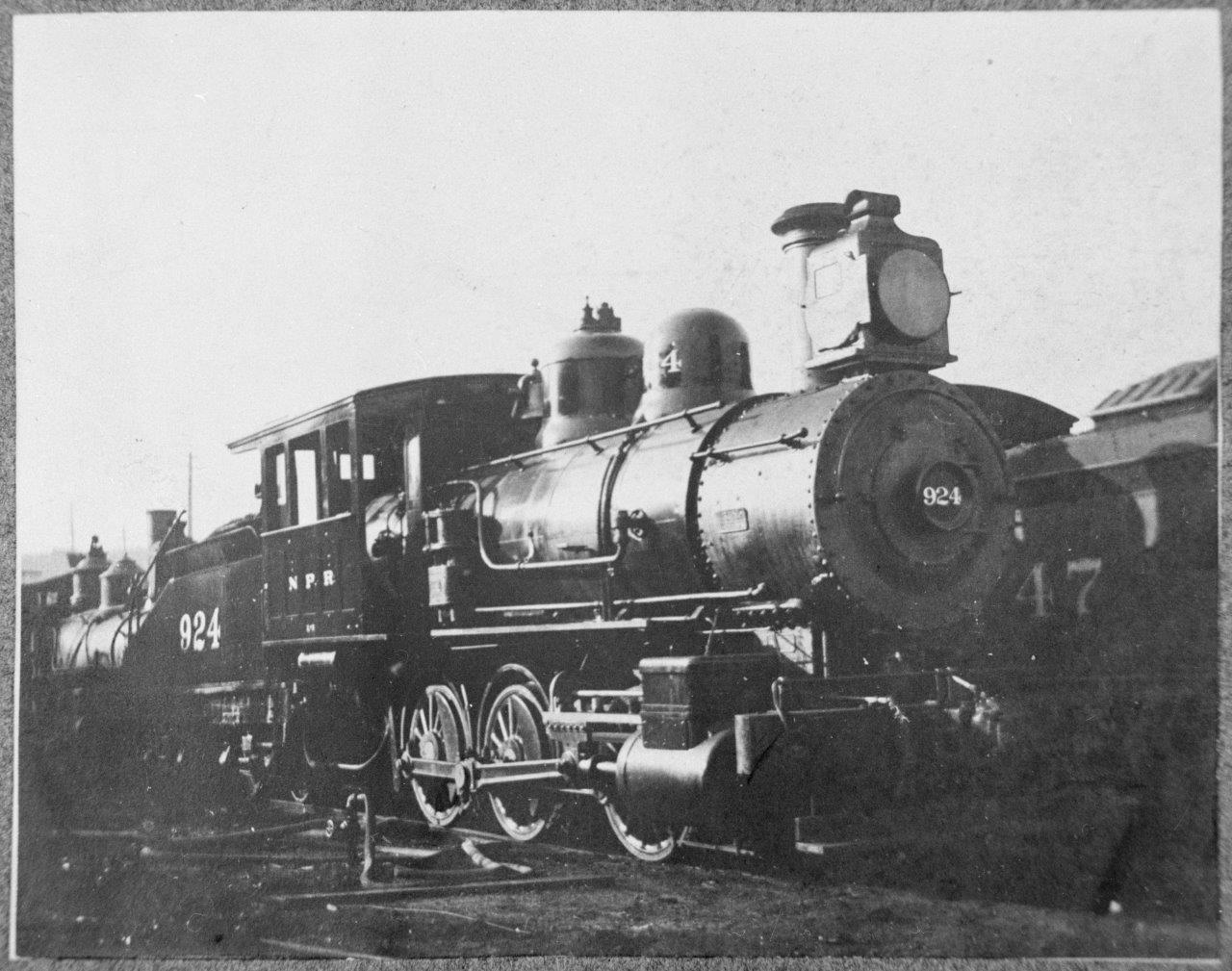

The Museum's former Northern Pacific Railway steam locomotive 924 has moved a little closer to operating under its own steam. This year rehabilitation of the locomotive appliances has been completed, and was undertaken by Bernie Watts at Backshop Enterprises. The Northwest Railway Museum is grateful for support from the Heritage Capital Projects Fund of the Washington State Historical Society - and the Washington State Legislature who approved this agency's appropriation - which funded this work.

Appliances perform a variety of functions. The air compressor provides compressed air for the brakes. The steam dynamo provides electricity for the headlights. The steam injectors provide a means for "injecting" water into the boiler while it is under pressure. The hydro-static lubricator uses steam pressure to push lubricating oil into the steam cylinder while it is operating.

The Westinghouse 9 1/2 inch steam driven air compressor is a relic from the early 20th Century. Many steam locomotives operating today have a more efficient cross-compound air compressor, but this single stage 9 1/2 was installed on locomotive 924 around 1910 and has remained there ever since. Unfortunately, it required extensive work, including replacement of the steam cylinder, the original of which was cracked. The compressor also required a new steam piston, piston rings, a variety of steam gaskets, oil cups, air valves, and more.

The Westinghouse 9 1/2 inch steam driven air compressor is a relic from the early 20th Century. Many steam locomotives operating today have a more efficient cross-compound air compressor, but this single stage 9 1/2 was installed on locomotive 924 around 1910 and has remained there ever since. Unfortunately, it required extensive work, including replacement of the steam cylinder, the original of which was cracked. The compressor also required a new steam piston, piston rings, a variety of steam gaskets, oil cups, air valves, and more.

The steam dynamo uses steam to spin a turbine. The shaft in the turbine spins an electric generator and produces direct current at 32 volts. This energy is used to power the headlights, but also for the cab lights. The era the Museum is representing with the 924's restoration is before the locomotive had an electric headlight. However the original-style oil lamp just isn't bright enough to allow for safe operation over the 20 public and private railroad crossings on the Museum's railroad. So the Pyle National K-240 steam dynamo has been fully rebuilt to its original specifications and will be used to power an electric headlight, though it will resemble an oil light.

The steam dynamo uses steam to spin a turbine. The shaft in the turbine spins an electric generator and produces direct current at 32 volts. This energy is used to power the headlights, but also for the cab lights. The era the Museum is representing with the 924's restoration is before the locomotive had an electric headlight. However the original-style oil lamp just isn't bright enough to allow for safe operation over the 20 public and private railroad crossings on the Museum's railroad. So the Pyle National K-240 steam dynamo has been fully rebuilt to its original specifications and will be used to power an electric headlight, though it will resemble an oil light.

The dynamo is a distinctive feature on most steam locomotives operating today. It emits a high-pitch whine while operating, and exhausts expended steam out a short stack. The Museum's K-240 was tested by Bernie Watts prior to shipping back to Snoqualmie, and the results were brilliant!

The dynamo is a distinctive feature on most steam locomotives operating today. It emits a high-pitch whine while operating, and exhausts expended steam out a short stack. The Museum's K-240 was tested by Bernie Watts prior to shipping back to Snoqualmie, and the results were brilliant!

The hydro-static lubricator lubricates the steam cylinders, including the steam side of the air compressor. Steam pressure is used to inject lubricating oil into steam cylinders while they are under pressure. The 924's lubricator was made by the Detroit Lubricator Company and has three feeds. It is a vital component, but the function can also be performed by a mechanical lubricator. Some steam locomotives in operation today have instead replaced the hydro-static lubricator with a mechanical lubricator. However, this lubricator is original equipment for the 924.

The hydro-static lubricator lubricates the steam cylinders, including the steam side of the air compressor. Steam pressure is used to inject lubricating oil into steam cylinders while they are under pressure. The 924's lubricator was made by the Detroit Lubricator Company and has three feeds. It is a vital component, but the function can also be performed by a mechanical lubricator. Some steam locomotives in operation today have instead replaced the hydro-static lubricator with a mechanical lubricator. However, this lubricator is original equipment for the 924.

The steam injector is an ingenious device that allows water to be injected into a boiler under pressure. The 924's original injectors mysteriously disappeared some years ago, but replacement injectors were acquired and have now been fully rebuilt to original specifications. Two Ohio type A number 8 injectors are now fully operational and ready to be an integral part of the 924's operation.

The steam injector is an ingenious device that allows water to be injected into a boiler under pressure. The 924's original injectors mysteriously disappeared some years ago, but replacement injectors were acquired and have now been fully rebuilt to original specifications. Two Ohio type A number 8 injectors are now fully operational and ready to be an integral part of the 924's operation.

Rehabilitating and restoring a steam locomotive to allow its operation is an expensive and complex undertaking, and your contributions will help complete the project. Rehabilitation of the appliances was just part of the equation, but also represents a very significant investment of time and materials. Historical research, technical specifications, regulatory compliance, funding, and project management are just a few of the many considerations that govern the outcome. Stay tuned for the next chapter!